My project for today was mounting the Shurflow 60psi, 1gpm fuel pump, as well as the fuel pressure regulator. I'm running out of real-estate in my "fashionably slim" frame, and had to situate it up front. I used my new favorite plumbing, aluminum flare, to make all the connections.

Theres a bulky pressure switch at the front of the pump, I won't be using this.

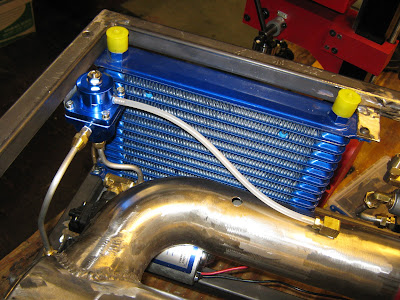

The plastic line connected to the pressure regulator is whats called a MAP (Manifold Air Pressure) reference line. In a car, this would be connected to the intake manifold downstream some forced air system, like a turbocharger. This pressurizes the back of the diaphgram in the regulator, allowing a constant pressure (relative to the "manifold" pressure) to be delivered to the injectors, no matter what kindof boost your making. Clever, huh?